Novel Problems Require Novel Solutions - Ninety One

This is the first in a series of articles where we are shining the spotlight on one of the most crucial areas of our business: our staff. We will be speaking to our team and getting their first-hand accounts of their role, the company and what makes our business tick.

The Design

Up first is our Design Director Steve Hubbard: Here at Thorpes we are often presented with the opportunity to utilise our team’s wonderful ability to think outside of the box when it comes to solving potentially tricky design issues, and Steve is one who revels in the chance to do so.

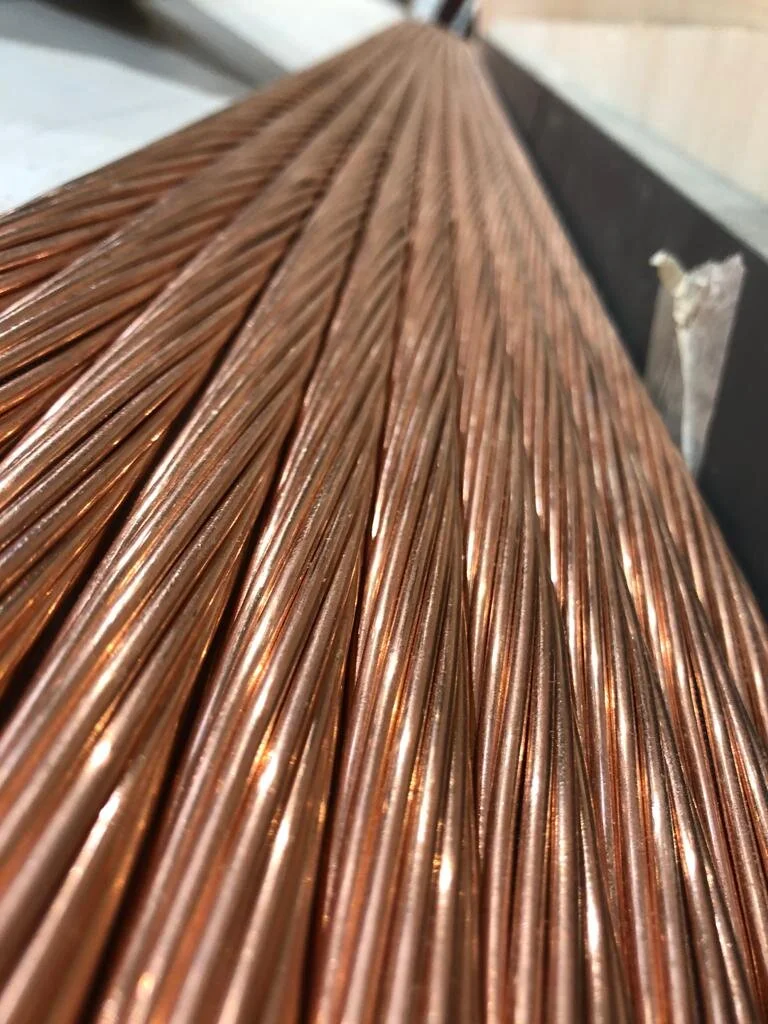

On this occasion we were presented with the challenge of creating metal bars, consisting of copper wire wrapped around a mild steel core 3m long, but, whilst this may sound like a simple matter of twisting a few strands the solution to this issue was certainly not straightforward.

In Steve’s own words there were numerous attempts:

“ Attempt 1: failed as both the jig and cables spent more time on the floor than the workbench.

Attempt 2: failed with the end result being four members of staff covered in sweat and a shop floor littered with copious amounts of scrap copper and a great deal of choice language.

Attempt 3: Turning to local engineering company with experience working on multiple components for various F1 motor racing teams we designed the ultimate twisting component. How could we fail? But fail we did, end result: more scrap copper.

At this time we considered doing something rarely, if ever, seen at Thorpes Joinery - admitting defeat. However, never wanting to be beaten we turned to one of our more “mature employees”. These guys are the backbone of joinery workshops up and down the country, they provide entertainment and guidance for the younger members of staff and possess a wealth of knowledge. Here at Thorpes we have several of these rather eccentric types, but we turned to Les, a Leicestershire legend with over 45 years experience in the trade.

After some extensive research, including a crash course in rope making, Les unveiled his invention, The ‘LWM1RTM’, and whilst his peers largely scoffed he proceeded to perfectly twist the first of 70 identical cables”.

Once pattenated with an antique white gold paint we will have achieved the challenging request set forth by our client, and both Les and Steve have yet another story to add to their growing collection, the true definition of turning concepts into reality.

In Production.

The Finished Product.